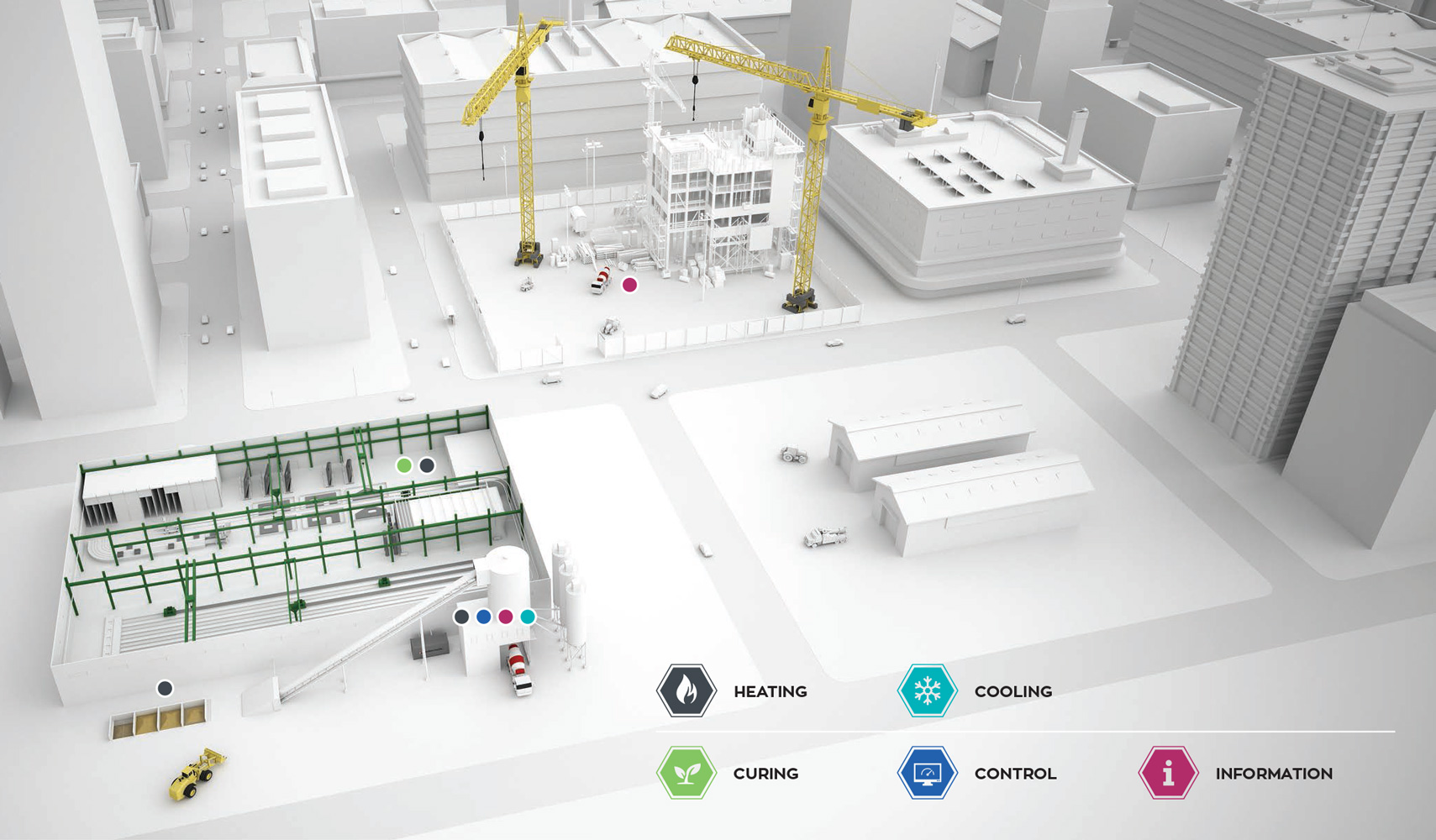

Polarmatic concrete heating, curing, cooling and control solutions

TOTAL SYSTEM SOLUTIONS

Polarmatic Oy is a world leading developer and supplier of innovative heating, curing, cooling, control and information management solutions specifically developed for the concrete industry.

Polarmatic provides optimum solutions for producers of ready-mix concrete in central-mix and dry batch batching plants as well as for producers of precast concrete, pipes, blocks and pavers.

ABOUT THE COMPANY

Polarmatic Oy was established in 1968. For more than 40 years Polarmatic has continued to be a leading developer of ground-breaking products and solutions for the concrete industry: from the infra-red oven for curing and the batching plant control system in the mid 1970’s to the innovative TURBOMATIC heating system developed by Polarmatic in the early 1980’s and the CUREMATIC curing system and the new generation ProconX control system of today.

Polarmatic’s main office and factory is located in Tampere, Finland. Polarmatic has a fully-owned subsidiary in Gothenburg, Sweden and a representative office in Moscow, Russia. All products are manufactured and assembled from high quality materials, components and equipment in Finland for concrete industry customers world wide. Sales and Service is supported by certified local partners.

Polarmatic offers total solutions - from process design & sizing of equipment and systems, to equipment delivery, installation and implementation of fully functional systems, complemented by preventive maintenance and technical services.

The innovative, high quality solutions enable customers to increase their annual production and produce higher quality concrete and concrete products in the most environmentally friendly manner - while at the same time save significantly in fuel, operating & maintenance costs.

Polarmatic’s solutions are today utilized by ready-mix producers in batching plants and by producers of precast concrete products, pipes, blocks and pavers all over the world. Even in the most demanding conditions.

EFFICIENTLY.

RELIABLY.

FLEXIBLE.

SUPERIOR HEATING POWER

Maximum production. High quality concrete. Significant savings… t all times, under all conditions - However cold…

The TURBOMATIC™ heating system is specifically developed to solve all heating needs in batching plants in the most efficient manner and more importantly to maintain the optimum concrete quality – both temperature and water-to-cement ratio - at all times.

THE MAIN FUNCTIONS OF THE TURBOMATIC ARE:

- quick melting of frozen aggregates

- pre-heating and heating of aggregates

- generation of warm dosing water

The TURBOMATIC is also capable of handling – at the same time, with a single unit – all other batching plant heating requirements such as:

- heating of batching plant production facilities

- heating of offices and other facilities

- generation of warm wash water/saddle tank fill water for truck mixers

- production of warm utility water

The TURBOMATIC heating system is available for all climate conditions and heating requirements: from areas with moderate, warm winter conditions to the coldest areas with the most severe winter conditions in the world as well as from small batching plants in small rural towns to the largest plants in the world’s largest metropolitan areas.

The TURBOMATIC heating system was developed by Polarmatic in the late 1970’s/early 1980’s on the behalf of the Finnish construction industry. Their aim was to be able to keep construction sites in operation during the winter months, however cold. For this purpose a reliable, high powered and energy efficient heating system capable of producing warm concrete with the optimum water-to-cement ratio was needed. The first TURBOMATIC was introduced by Polarmatic in 1982. Today there are almost 1000 TURBOMATIC heating systems in operation all over the world.

THE TURBOMATIC HEATING SYSTEM OFFERS NUMEROUS BENEFITS:

- Increased annual concrete production - as there is no reduction in production capacity even during the coldest of winters - due to superior heating power

- Production of high quality concrete with optimum water-to-cement ratio and temperature at required capacity and at all ambient (temperature) conditions

- Significant savings in fuel consumption – as high as 60-80%

- Lowest possible operating costs - due to no annual inspections, no separate, certified operating personnel, no special requirements for water…*

- Lowest possible maintenance costs - designed and built for demanding conditions utilizing only high quality components and equipment

- Environmentally friendly - due to lowest possible fuel consumption, lowNOx-burner technology, no generation of any wastes whatsoever

- Fully automatic, PC-operated – and thus fast, flexible and reliable as well as easy-to-operate

* The TURBOMATIC heating unit is not classified as a boiler or pressure vessel

PRECISELY CONTROLLED, OPTIMIZED CURING

Faster throughput. increased production.

High quality products… Precisely. Cost-efficiently

The CUREMATIC™ curing system is specifically developed to solve all curing needs in precast concrete, pipe, block and paver plants in a precisely controlled, optimized and energy-efficient manner.

THE MAIN FUNCTIONS OF THE CUREMATIC ARE:

- curing in chambers and kilns with CO2-rich TURBOsteam, hot air or steam

- curing of hollow core slab beds with warm water

The CUREMATIC is also capable of handling all other precast concrete, pipe, block and paver plant as well as associated batching plant heating requirements such as:

- quick melting of frozen aggregates

- pre-heating and heating of aggregates

- generation of warm dosing water

- generation of warm wash water/saddle tank fill water for truck mixers

- production of warm utility water

- heating of plant and production facilities

- heating of offices and other facilities

The CUREMATIC curing system is a total system solution from process design & sizing of equipment, to delivery, installation and implementation of a fully functional curing system including the equipment and controls needed for an optimum curing process resulting in high quality concrete products.

THE CUREMATIC CURING SYSTEM OFFERS NUMEROUS BENEFITS:

- total system solution for curing and heating

- precise control of the curing process

- increased annual production due to superior heating power and/or use of warm concrete

- production of high, constant and homogenious quality end-products with warm, high quality concrete

- significant savings in energy consumption and cost – as high as 80%

- savings in cement usage and cost – as high as 5%

- lowest possible operating costs

- lowest possible maintenance costs

- environmentally friendly - minimum fuel consumption, minimized cement consumption, lowNOx-burner technology, no wastes

- fully automatic, PC-operated - Optimised, precise control throughout the entire process – from batching to curing including continuous follow-up and monitoring with easy to use reports, full traceability, etc, calculated maturity etc.

HIGH EFFICIENCY COOLING

High quality concrete… Easily. Flexibly. Cost-efficiently…

The COOLMATIC™ cooling system is specifically developed to solve batching plant cooling needs in the most effective and cost efficient manner.

THE MAIN FUNCTIONS OF THE COOLMATIC ARE:

- generation of cold dosing water

- storage of cold water

The COOLMATIC provides a total cooling solution, including all the necessary equipment for production, storage and dosing of cold or ice water:

- water chiller with accessories

- cold water storage with dosing water pump and accessories

- piping systems (internal)

- instrumentation and controls

- necessary stairs and access platforms

The COOLMATIC cooling system is designed for the following dosing water temperatures:

- COOLMATIC cold water system +5 ºC

- COOLMATIC ice water system +1 ºC

The COOLMATIC cold and ice water units can be supplied as a stand-alone system or integrated with Polarmatic’s TURBOMATIC heating system to provide a combined heating and cooling solution.

THE COOLMATIC COOLING SYSTEM OFFERS NUMEROUS BENEFITS:

- total, compact cold or ice water system with all necessary equipment for production, storing and introducing cold and or ice water to the concrete manufacturing process

- possibility to integrate cooling with the plant heating systems (COOLMATIC+TURBOMATIC)

- ultra high efficiency – high quality water chiller

- high full load efficiency and excellent partial load efficiency resulting in considerable savings in the electricity consumption

- closed, indirect system for maximum safety, reliability and flexibility

- environmentally friendly solution and refrigerants

- fully automatic, PC-controlled system

- lowest possible operating and maintenance costs

- use of of high quality materials, components and equipment only