pipe plants and other used concrete product manufacturing equipment 1-888-503-8812

- Home

- Company Profile

- Used Equipment

- New Equipment

- Plant of the month

- Contact

Purchasing and selling

Used concrete plants and used equipment related to concrete product manufacturing

YOU ARE A BUYER OR SELLER

of used concrete equipment?

INFORMATION FOR BUYERS INFORMATION FOR SELLERSCURRENT BEST DEALS

-

Manufactureur

Columbia

Model

22 HF

Description

Used 1995 Columbia 22HF block machine with PLC controls.

-

Manufactureur

Besser

Model

Ultrapac

Description

Used 1994 Besser Ultrapac block plant

C/w:

Used Besser Ultrapac – 4 block machine

• Ultrapac machine

• Pallet conveyor

• Pallet return conveyor

Used Bessermatic handling system with LSC-40

• LSC40

• Loader/Unloader Besser multi-spade m9 no frame

• Depalleter

• Block turnover

2 Molds

Spare parts

Dismantled in 2017.

Excellent condition as it was overhauled before being shut down.

-

Manufactureur

Besser

Model

Dynapac

Description

Used Besser Dynapac plant

Comes with:

Besser Dynapac block machine pallets size 740x520 mm, Smartpac vibration, T30 panel view

Front delivery linePallet return conveyorBesser matic stackers plus spades plus frame assembly plus control panelDepalaterRack conveyorLsc 40 car crawlerSide shifter for rack conveyor -

Manufactureur

E&R

Description

Used 1987 E&R CM-24 HF 24 inch splitter with self leveling blades

Hydraulic unit

Controls

-

Manufactureur

Colle

Model

Vibromatic

Description

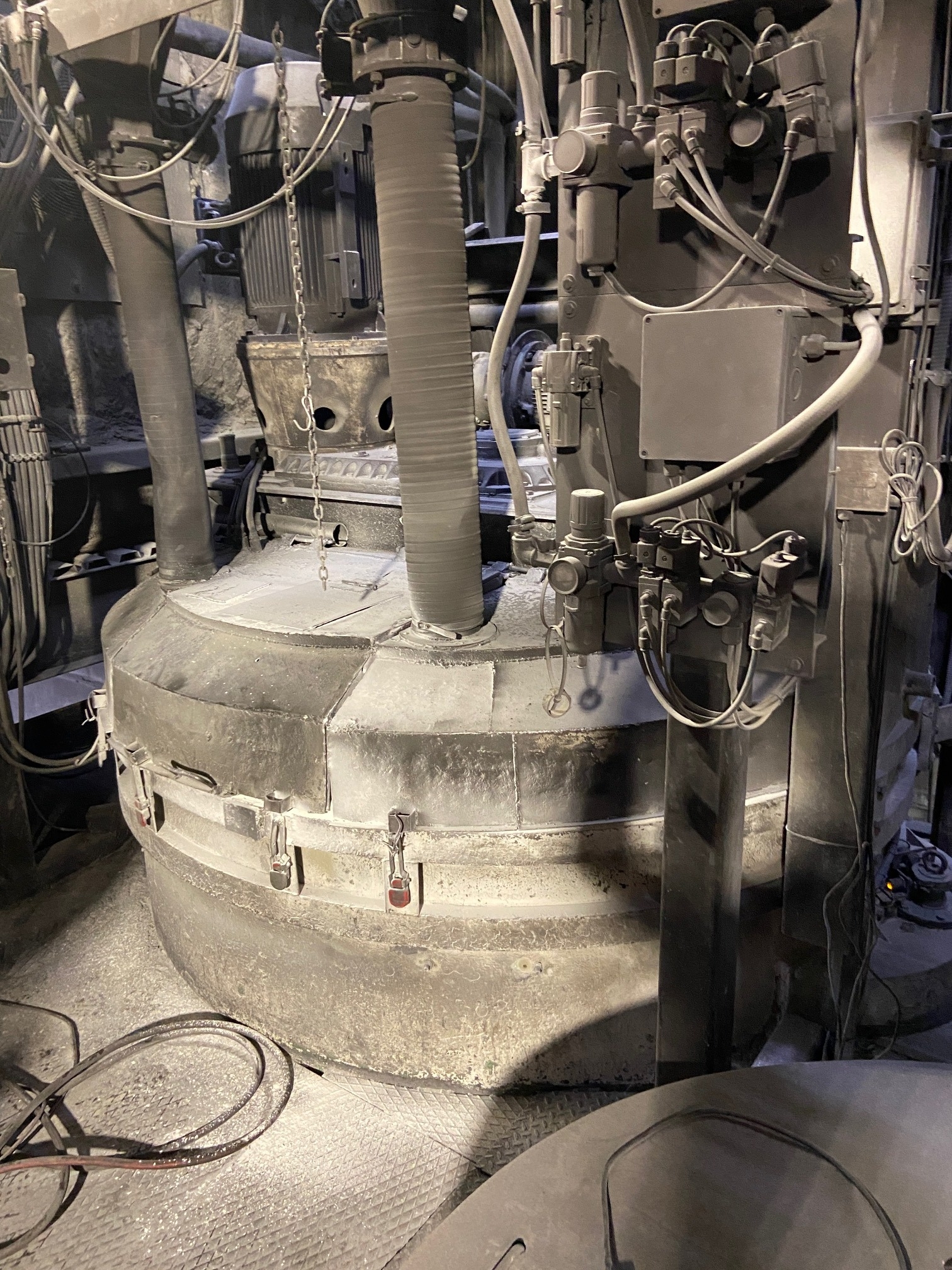

Used Colle COLLE SpA. Type Vibromatic 30/200 pipe machine. It is in great condition with only 3000 operational hours. It is operational at the moment and in production status.

Item Description

Name Description ID Tag Category Date Supplier Condition Qty VIBROMATIC 300/2000 Automatic Pipe Machine VM01 Production line 01-10-2010 COLLE Excellent 1 VIBROMATIC Moulds Double Production Moulds for pipe production VM01/400 Pipe equipment 01-10-2010 COLLE Very Good 2 Double production with DN600 Moulds for pipe production VM01/500 Pipe equipment 01-10-2010 COLLE Very Good 1 Double production with DN500 Moulds for pipe production VM01/600 Pipe equipment 01-10-2010 COLLE Fair 1 Moulds for pipe production VM01/800 Pipe equipment 01-10-2010 COLLE Very Good 1 Moulds for pipe production VM01/1000 Pipe equipment 01-10-2010 COLLE Excellent 1 Moulds for pipe production VM01/1200 Pipe equipment 01-10-2010 COLLE Excellent 1 Rings for pipe production VM01/400R Pipe equipment 01-10-2010 COLLE Excellent 140 Rings for pipe production VM01/500R Pipe equipment 01-10-2010 COLLE Excellent 85 Rings for pipe production VM01/600R Pipe equipment 01-10-2010 COLLE Excellent 85 Rings for pipe production VM01/800R Pipe equipment 01-10-2010 COLLE Excellent 95 Rings for pipe production VM01/1000R Pipe equipment 01-10-2010 COLLE Excellent 70 Rings for pipe production VM01/1200R Pipe equipment 01-10-2010 COLLE Excellent 70 VIBROMATIC - Master Donkey Fresh Pipe Transport MDONKEY Pipe equipment 01-10-2010 COLLE Excellent 1 -

Manufactureur

Colle

Model

Vibromatic

Description

Used Colle COLLE SpA. Type Vibromatic 30/200 pipe machine. It is in great condition with only 3000 operational hours. It is operational at the moment and in production status.

Item Description

Name Description ID Tag Category Date Supplier Condition Qty VIBROMATIC 300/2000 Automatic Pipe Machine VM01 Production line 01-10-2010 COLLE Excellent 1 VIBROMATIC Moulds Double Production Moulds for pipe production VM01/400 Pipe equipment 01-10-2010 COLLE Very Good 2 Double production with DN600 Moulds for pipe production VM01/500 Pipe equipment 01-10-2010 COLLE Very Good 1 Double production with DN500 Moulds for pipe production VM01/600 Pipe equipment 01-10-2010 COLLE Fair 1 Moulds for pipe production VM01/800 Pipe equipment 01-10-2010 COLLE Very Good 1 Moulds for pipe production VM01/1000 Pipe equipment 01-10-2010 COLLE Excellent 1 Moulds for pipe production VM01/1200 Pipe equipment 01-10-2010 COLLE Excellent 1 Rings for pipe production VM01/400R Pipe equipment 01-10-2010 COLLE Excellent 140 Rings for pipe production VM01/500R Pipe equipment 01-10-2010 COLLE Excellent 85 Rings for pipe production VM01/600R Pipe equipment 01-10-2010 COLLE Excellent 85 Rings for pipe production VM01/800R Pipe equipment 01-10-2010 COLLE Excellent 95 Rings for pipe production VM01/1000R Pipe equipment 01-10-2010 COLLE Excellent 70 Rings for pipe production VM01/1200R Pipe equipment 01-10-2010 COLLE Excellent 70 VIBROMATIC - Master Donkey Fresh Pipe Transport MDONKEY Pipe equipment 01-10-2010 COLLE Excellent 1 -

Manufactureur

Colle

Model

Vibromatic

Description

Item Description

Name Description ID Tag Category Date Supplier Condition Qty VIBROMATIC 300/2000 Automatic Pipe Machine VM01 Production line 01-10-2010 COLLE Excellent 1 VIBROMATIC Moulds Double Production Moulds for pipe production VM01/400 Pipe equipment 01-10-2010 COLLE Very Good 2 Double production with DN600 Moulds for pipe production VM01/500 Pipe equipment 01-10-2010 COLLE Very Good 1 Double production with DN500 Moulds for pipe production VM01/600 Pipe equipment 01-10-2010 COLLE Fair 1 Moulds for pipe production VM01/800 Pipe equipment 01-10-2010 COLLE Very Good 1 Moulds for pipe production VM01/1000 Pipe equipment 01-10-2010 COLLE Excellent 1 Moulds for pipe production VM01/1200 Pipe equipment 01-10-2010 COLLE Excellent 1 Rings for pipe production VM01/400R Pipe equipment 01-10-2010 COLLE Excellent 140 Rings for pipe production VM01/500R Pipe equipment 01-10-2010 COLLE Excellent 85 Rings for pipe production VM01/600R Pipe equipment 01-10-2010 COLLE Excellent 85 Rings for pipe production VM01/800R Pipe equipment 01-10-2010 COLLE Excellent 95 Rings for pipe production VM01/1000R Pipe equipment 01-10-2010 COLLE Excellent 70 Rings for pipe production VM01/1200R Pipe equipment 01-10-2010 COLLE Excellent 70 VIBROMATIC - Master Donkey Fresh Pipe Transport MDONKEY Pipe equipment 01-10-2010 COLLE Excellent 1 -

-

Manufactureur

Columbia

Model

16 pit model

Description

Used fully refurbished Columbia 16 pit model 3 at a time block machine with PLC controls

16-h-3e-3 exact model

-

Manufactureur

KTB Machinery

Description

Used "State of the Art" wet cast pipe plant and simply makes the best and smoothest concrete pipes ever made.

BlueTube wet Cast Batching Machinery

Comes with:

Concrete pump.

Fillings units (from top and bottom).

2 x Mould handling units (opening and closing).

Transport carts.

Discharging unit.

Reinforcement placing crane.

Computer Operating system.

Crane in mould warehouse.

Other production materials.

3 x robots for cleaning and spraying.

175 moulds available

Batching machinery complete can be purchased separately.

-

Manufactureur

Dacem

Model

3,000 liters

Description

Used 2017 Dacem pan type mixer.

3 discharge doors

-

Manufactureur

Besser

Model

Dynapac

Description

Used Besser Dynapac plant

Comes with:

Besser Dynapac block machine pallets size 740x520 mm, Smartpac vibration, T30 panel view

Besser matic stackers plus spades plus frame assembly plus control panel -

Manufactureur

Putzmeister

Model

TK-50

Description

Used Putzmeister TK-50 trailer concrete pump

2014

1450 hrsComes with remote controlNo piping -

Manufactureur

Form Impianti

Model

FI1200 1100x1200mm

Description

Used Form Impianti board machine model Fi1200

1100x1200mm board size

Fully Refurbished

Comes with:

Spare parts and vibrators

Conveyors

Siemens plc controls

No drives

Complete

Self lubricated vibrators

Transfo 575 to 480v

Machine can be operated 480v or 575v

Hydraulic unit with proportional valves

Pallet feeder

Spare parts

Already dismantled and ready to ship

-

Manufactureur

Oru

Description

Used batching system made by Benoît Foret

C/w:

40 ton cement silo, 8 feet diamater with cement fill pipe. No dust collector

3 Aggregate bins ofg 6 tons each

Weighing connveyor on load cells

1 cubic meter Oru mixer

40' approx Vbelt conveyor with new belt

PLC controls

-

Manufactureur

Columbia

Model

22 pit style

Description

Used Columbia 22 Pit style complete plant. Sill installed. Can be seen dry cycled.

Comes with:

1976 Columbia 42 c.ft. mixer model 308-262-1-3. New Spiral blades in 1998. New pillow blocks and bearings in 2008. New pinion gear and large spur gear in 1990.

1967 Columbia Load Sensor Mix Mizer batch plant with an updated

Toledo (1992) electronic load cell cement scale and a computerized water

metering system in 2000. Two separate complete load sensor batch plant controls

(1974) purchased from other factories who upgraded their systems. Each has

several replacement modules such as moisture meters stepper switches etc.,

several of these being brand new.

Columbia 28 c.ft. skip hoist and hopper modified to accommodate the 42 c.ft.

Mixer by increasing height of bucket and doubling the pulleys to increase load capacity of hoist and steel cable.

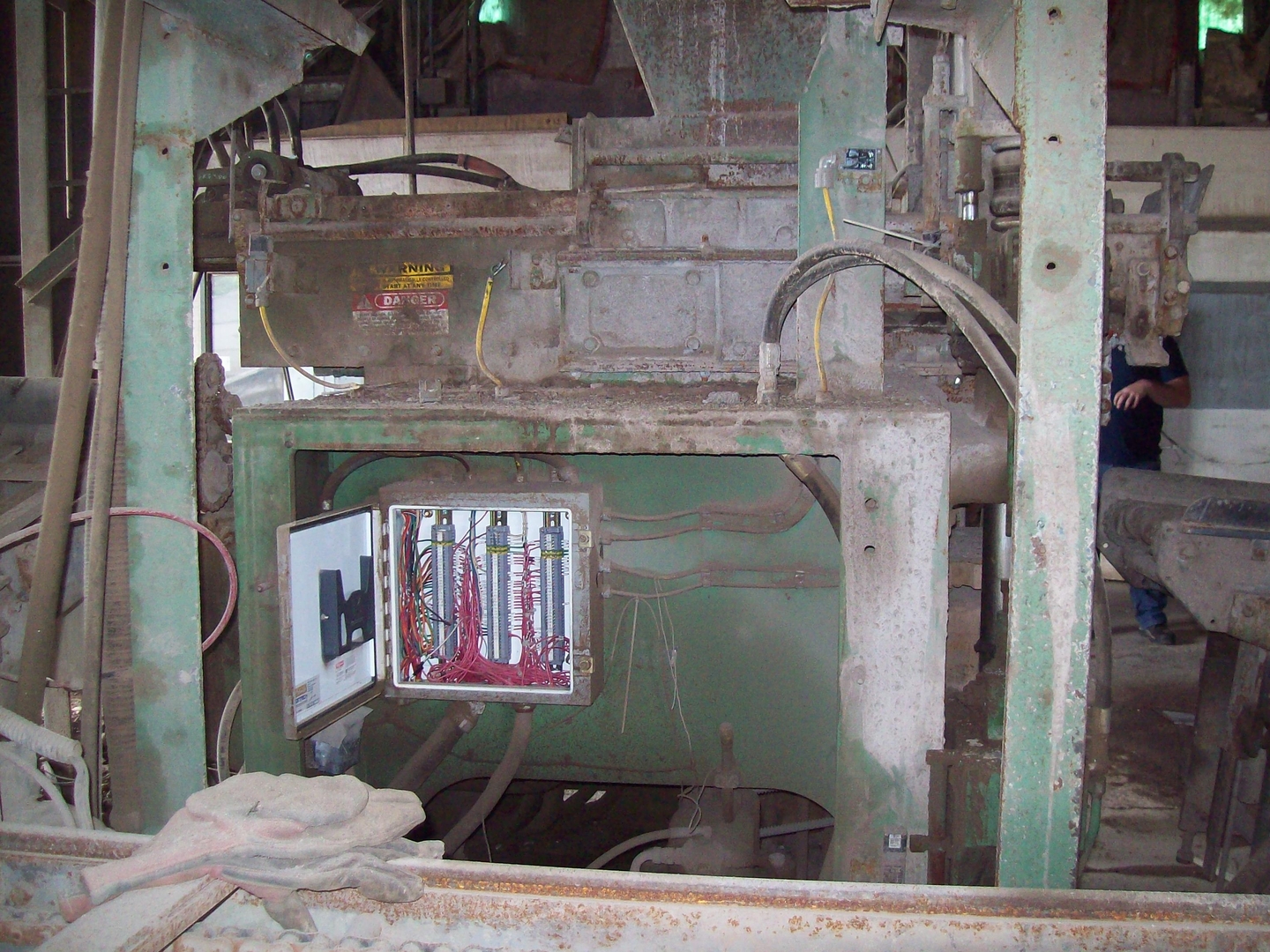

1985 Columbia Model 22 H block machine with air bags on the head and

pallet table. Controlled by a Texas Instrument 5TI PLC.

1974 Columbia UL20 hydraulic powered rack loader unloader. Upgraded with a Dynco pallet scraper (1990). Replaced original Columbia hydraulic valves with self centering outboard mounted valves in March 2012.

1974 Cleaner and oiler return conveyor model #303-131-1

1974 Columbia model #440-15-1 clamp block turnover upgraded with a belt conveyor in 1999

1974 Columbia No.2 semi automatic cuber modified to use electronic eye table

height control with direct electrical control of the solenoid valve.

Air compressor

Related hydraulic units

Spare parts

2100 18 x 20 x 1/4” steel pallets exact quantity to be confirmed

53 3 bay, 6 high, 2 deep steel racks, 9-3/4” spacing between shelves. Proper size to use with UL20 Columbia loader/unloader.

1980 Complete metric hollow block mold package to make 5cm solids, 10, 15, 20, 25,

30cm stretchers. 25 and 30cm L corner molds. Parts to make scored,

bond beams, solids, semi solids, etc.

1990 Molds with heated shoes and heater control unit to make three shapes of paving stone such as Brick (Holland), Uni Decor and Uni Stone

1990 Two molds to make two types of retaining wall blocks

1986 Columbia kiln control units. Four separate units to control

six kilns. Each kiln can store 1000, 20cm equivalents or 1000, 25cm regular

blocks for a total daily capacity of 6000, 25cm regular blocks equivalents

-

Manufactureur

Hans Pedersen

Model

HP 619

Description

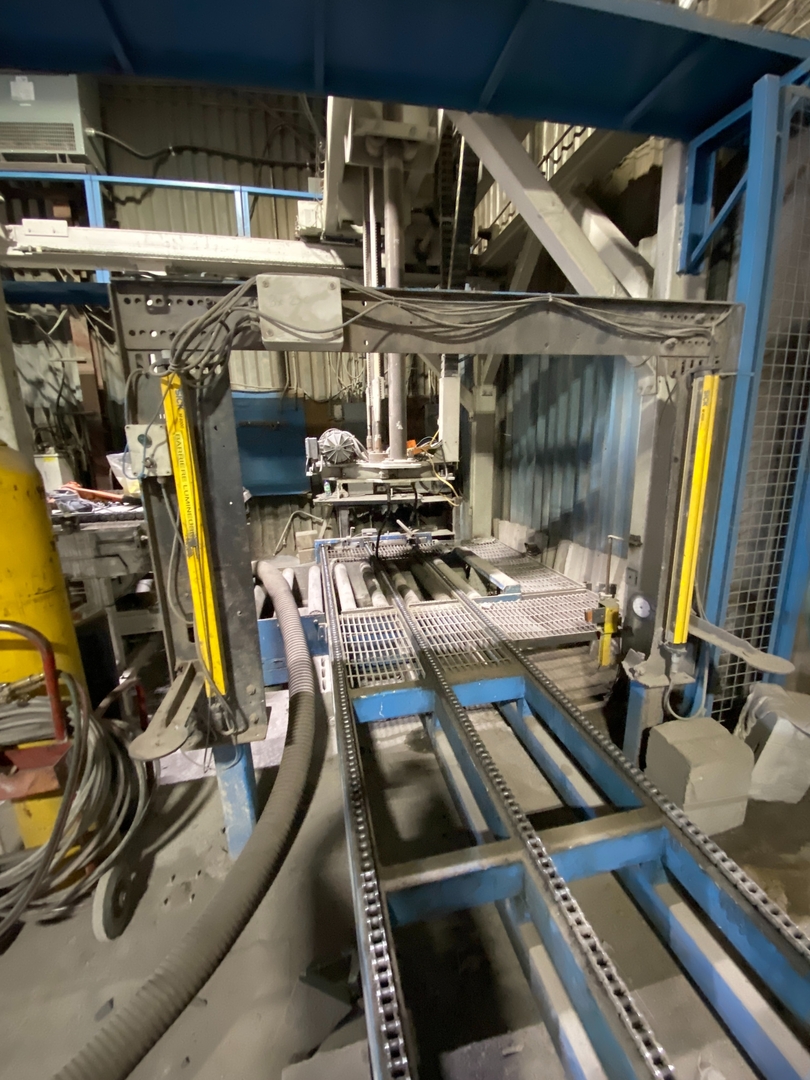

Used Hans Pedersen complete splitting line.

Comes with:

Clamp feeding system (shown dismantled on picture) on chain conveyor to feed product cubed on wooden pallet 90 degree transfer to

Auxiliary chain pusher feeding system (encoder controlled)

2-way hydraulic splitter. 45.5 inch blade (multiple straight blades in 6'' sections and one X shaped blade). Can split from 60 to 180 mm max

Underneath pallet conveyor to bring wooden pallet to cubing station

Slat conveyor

Clamp cuber with scisor lift to recube product on wooden pallet

1 section of chain conveyor over scisor lift cubing station

Siemens PLC controls on platform over the splitting line

Hydraulic unit

Electrical panels

Guards

Stopped producing in april 2023. Now disamntled (Controls wires were cut at motors)

Value new: EUR 450,000

-

Manufactureur

-

Description

3 aggreate hoppers on 3 load cells each with 3 individual dosing conveyors

Capacity 6,500 KG each

-

Manufactureur

-

Description

Two V Belt conveyors.

35' -10'' long (Belt 30'')

48' long (Belt 36'')

-

Manufactureur

-

Model

110 ton

Description

Used 110 ton cement silo

Comes with ladder, rest basket and top ramp. Dust collector.

Dimensions:

Diameter: 9'

Straight shell: 38.5'

Cone: 7'

-

Manufactureur

KVM

Model

1200 90/105

Description

Update: Complete paver plant available including land and building in Quebec, Canada.

Used 2003 KVM 1200x1000 Single-layer dry cast press for pavers, SRW and concrete blocks

Excellent condition

Comes with:

3 V-Belt conveyors: 24" x 15' (For cleanup)

24" x 33' (From mixer to the 3 concrete hoppers)

18" x 17' (From the 3 concrete hoppers to KVM machine hopper)

Elementis color distribution system (powder type pigments) with 4 pneumatic stations Weigh-Tronix balance for pigments model DS2424A with Telemecanique PLC controls.

3 concrete hoppers with feeding distribution system from single mixer (mixer not included) with Computerized Control panels to make color blends. Each bin has a small belt conveyor underneath to feed the 18" x 17' V belt conveyor to KVM machine hopper.

2003 KVM Model 1200 90/105 block and paver concrete dry cast press.

New feeding drawer installed in 2021. Integral frame, never cracked or repaired.

Facemix not included but could be added by KVM.

Max Recommended Demolding Area: 1,080 x 960 mm (42-1/2 x 37-3/4 in)

Estimated Product Height range: 50 to 300mm (2 to 12in)

Estimated Press cycle:

Pavers 4'' x 8'' - 60mm (40 units) – 13-16sec. 248 average cycles/hr at 14.5sec. Represents 2,202 sq.ft./hrs (204.5 sq.m./hrs)

Blocks 6’’ x 8'' x 16'' (14 units) – 13-16sec. 248 cycles/hr average at 14.5sec. Represents 3,472 blocks/hrs

Block Qualifier Automated laser product height measuring system model GT-5 with controls.

KVM Automatic Elevator and Lowerator with transfer car handling system 22 high for wet and dry product handling system.

Can handle thin products 22 boards high or thicker 90 mm and more high product 11 high.

Curing chamber 8 tunnels, 22 levels x 12 deep.

KVM palletizer clamp Cuber system that can rotate to cross layers with wooden pallet magazine.

Board brushing and oiling station.

Board flipping station.

Automatic pallet dolly on rail to transfer empty Wasa boards to KVM press.

Motorized conveyors.

Wulftec horizontal stretch wrapper model WRTA-150. Plastic film, average time 13.6sec./cycle.

Long slat exit conveyor with Cornell building exit door system.

Approximately 1670 1200x1000x45 mm Wasa composite boards. Very good condition. Used on both sides. (600 new from 2022)

Approximately 10 molds from various manufacturers (KVM, Rampf, Kobra, etc …)

Used Vena 48 inch splitter. Comes with ACP bar feeding system, plc controls and hydraulic unit

Related Hydraulic power packs, Electrical cabinets, PLC controls, security fencing.

Related spare parts.

Ventex 8,000 CFM Dust Collector model KG2 for dust collection of concrete press and board brushing station. Has extra capacity to handle other dust collection requirements.

Cement silo 60 Ton, Aggregate bins, mixer.

Lift trucks

Multiple buildings including office, aggregate and sand storage

Show room

-

Manufactureur

-

Model

60 ton

Description

Used self erecting 60 ton cement silos

Two compartments: Bin 1 is 500 cu. ft. and bin 2 is 2000 cu. ft.

Comes with 3 solar pannels on each sides (6 total per silo) and battery system to power up the hydraulic system for self erection

Dust collector connection is there but no dust collector included

Sandcastle ps2500

dual ram hoist

air suspension

air brakes tandem axle steel wheels

11r225 tires

GVWR.61.500 lbs.

48 feet longx119 inches wide overall

2,500 cf capacity

7 silos are available

Note: No dust collection or cement auger included.

-

Manufactureur

-

Model

80 ton

Description

Two used cement silos

10 feet diameter

60 feet long (40' long drum)

Comes with legs and cement loading pipe

Ladder inside.

-

Manufactureur

Vihy

Description

VIHY Rimamat pipe plant manufacture in 1995.

The Rimamat plant is fully automated for the production of circular or pre-bedded concrete

pipes from ø 300 mm to ø 1250 mm in lengths of 2,0 m. The machine is in good condition

and is very versatile. It can also produce manhole sections and cones.

SCOPE OF SUPPLY:

? Rimamat complete Plant.

? Pallet automation with oiling of pallets.

? Filling box with distributor device.

? 2 V 30S-40 Stepless hydraulic vibrator control.

? Pipe transport truck, electrical.

? Quick mould change.

? Falcon computer control.

Dialog/Menu.

Machine setting.

MOULD EQUIPMENT FOR PIPES WITH PREBED.

? Ø 300 mm,

? Ø 400 mm,

? Ø 500 mm,

? Ø 600 mm,

? Ø 700 mm,

? Ø 800 mm,

? Ø 1000 mm.

? Lengths 2,0 m.

? Pallets, set rings and other accessories included.

MOULDEQUIPMENT FOR MANHOLE SECTIONS AND CONES

? Ø 1000 mm x 250 mm.-1000 mm sections.

? Ø 1000 mm x 600 mm – 1100 cones.

? Ø 1000 mm cone part.

? Pallets, set rings and other accessories is included.

The machine can produce 2 pipes from Ø 300 mm and up to Ø 600 mm, and 1 pipe from

Ø 700 mm and up to Ø 1200 mm.

-

Manufactureur

-

Description

Used concrete batch plant

Comes with:ItemsA Used concrete silo with sub-structure 36 bags dust collector, cement loading pipe. Cylinder diameter? Cylinder height? Cône height? Total height?B Two split aggregate bins (4 total bins) with a capacity of ? Tons each setup on substructureC V-Belt conveyor 15''x20'D Cement auger 6'' diameter x 20' longE 1 cubic yard concrete mixer with 50 HP motor and substructureF 1 weighing bin on four load cells. 30,000 KG useful capacity, 1,400 KG real capacity. Manufacturer Rice Lake Avery Weigh, Model IQ-355-2A.G Multi Mix controls.H CompressorI (Dust collector listed with the silo)J Two concrete recipients with a concrete pumpK 15 single axle concrete trailers -

Manufactureur

-

Description

Used batching system30 Ton square Cement silo including cement auger and dust collector1 yard to 1.5 yard Sicoma pan type mixer (approx 2010) with cement auger2 Aggregate bins with a capacity 5 ton each approx with dosing system, skip hoist on load cells, Marcotte controls -

Manufactureur

-

Description

2 Aggregate bins with a capacity 5 ton each approx with dosing system, skip hoist on load cells, Marcotte controls

-

Manufactureur

Di-Coat Corporation

Model

DCC-Z500 Masonry Thru-Feed Grinder

Description

Used 2014 Di-Coat Corporation concrete product 3 head grinder

Model DCC-Z500 Masonry Thru-Feed Grinder

The DCC-Z500 Masonry Block Grinder is a heavy- duty machine designed for high production face grinding of CMU’s using “Di-Coated” Diamond Drums and / or vertical spindle wheels. The modular grinding station setup offers the rapid stock removal of diamond drums and the excellent finish of a vertical spindle diamond disc. Sequential power-up of motors helps cut power cost and prevents power surge.

Dimensions:

- Machine: 5′ wide x 16′ long x 10′ high

- Electrical Control Box (Free-Standing): 1′ wide x 6′ long x 5′ high

Weight: 18,000 lbs

Motor:

- Roughing Station (Drum): 30 HP Severe-Duty

- Semi-Finishing Station (Drum): 30 HP Severe-Duty

- Finishing Station (Drum): 15 HP Severe-Duty

- Extra Fine Finishing Station (Disc): 15 HP Severe-Duty

- 480 Volt – 3 Phase Optional: (240 Volts)

Coolant Requirement:

- 10-12 gal./min./station

- Coolant Delivery/Cleaning Manifolds

- Thru-Spindle Coolant Of Vertical Heads

Production Rate:

- Three Programmable Speeds Producing 12-18 Blocks/minute.

- 22 Blocks/minute maximum

Machine Features:

- Rigid, heavy-duty welded construction

- Belt/Platen multiple speed conveyor system (8-10-12 ft./min.)

- Modular grinding cell configuration Accommodates up to four stations Head Spindles

- Diamond Grinding drums skewed for improved finish & extended life

- Special belt drive system to suppress noise levels

- Centralized grease fittings

- Ergonomic design

Block Height Adjustment:

- Microprocessor controlled height adjustment for block size changes

- Pre-programmed settings for 4, 6, 8, 10, 12″ CMU’s & 16″ specialty blocks

- Height adjustment of all grinding stations can be lowered uniformly for grinding opposite side of block — at push of a button

- All heads simultaneously move up & down automatically determined by

restrictor bar position - Push-button manual over-ride to change grind depth to non-standards

- Hand-held “Zero-Out” control for calibrating individual drums & vertical wheels

- Safety Feature–Automatic block height restrictor bar to prevent crashes

Drum Information:

- Quick & easy diamond drum or disc change-over

- Drums can be recoated by Di-Coat Corp. using high grade GE Diamond

- Reconditioned or new drums supplied ready to mount with pre-installed pillow block bearings

Control Panel:

- Free-standing control panel permits ease of operation & floor space optimization

- Display prompts operator of required action

- Single command to select 1st, or 2nd, side grind height

- Digital display of fine adjustment of grinding heads

- Each grind station may be individually active or off-line

- Analog display of amperage draw for each grind station

- Pause mode stops conveyor but leaves grinding heads running

- Programmable stock removal setting for each station

- On-screen programming

-

Manufactureur

Columbia

Model

924

Description

Used 1990 Columbia block 924 splitter with

Infeed belt conveyor

Hydraulic unit

-

Manufactureur

Besser

Model

Servopac

Description

Used 2004-2009 state of the art Besser Servopac 3 at a time complete block plant

Servopac benefits:

- All hydraulic vs the vibrapac and Dynapac mechanical systems

- 5 to 7 cycles per minute depending on product

- Quick mold change ( 20 minutes)

- Quick height change (20 minutes)

- Low maintenance

- Easy cleaning

Comes with:

Servopac block machine (2009)

Block Feeding Station (2009)

Pallet Placing System (2009)

Front Conveyor

Stacker

Loader Spade

Rack Conv and Side Shifter

LSC-40 Car and Crawler

Kiln Door

Unloader Spade

Desacker

Unloading Conv 1

Depalleter (PushOff)

Turn Table at Depalleter

Pallet Scraper

Unloading Conveyor 2

Pallet Turn Over

Pallet Box and Return Conv

Line Conveyor

Cuber 3 turnatble Pattern Maker

Cuber Side Feed

Main Cuber Core

Skid Dispenser

Exit roller conveyor

99 racks 9 high, 5 deep, 3 wide (135 pallets per rack)

4,800 steel pallets 18 1/2 x 26 inches

Allan Bradley SLC500 PLC controls

Related hydraulic units

Molds, air compressor, splitter and block turnover not included.

-

Manufactureur

Omag

Model

1200x1100

Description

Used 2007 Omag 1200x1100 Board machine block and paver plant

Comes with:

Cement silo and auger

ACT/ Wiggert 1875 L Mixer

Eagle Granular Colour Machine

Marcotte Batching System

Besser / Omag Concrete Transfer Conv System

Omag Concrete Hopper System

Omag Block Machine (No face mix). 2.8 to 3 cycles per minute. Was producing 36 to 90 mm high products

Omag Wet Conv (Front)

Omag Material (Board) Dumper

Omag Elevator

Omag Finger Car

Omag Lowerator

Omag Gap Closer

Omag Dry Conv to Cuber

Omag Cuber Skid Dispenser

Omag Skid and Cube Conv

Omag Cuber

Omag Board Brush and Flipper

Omag Rear Board Return Conv

Omag Board Return Conv

Omag Power Supply Panels

Omag Wet Side Hyd Unit

Omag Dry Side Hyd Unit

Siemens PLC controls

Steam generator

1220 Used plastic production boards size 1200x1100 mm (1040x1040 mm production area)

Available mid 2026

-

Manufactureur

Besser Lithibar

Description

Used 2000 Besser Lithibar automatic cuber

C/w 3 turntable pattern former

Hydraulic unit

PLC controls

-

Manufactureur

OCEM

Model

Hermetic

Description

Used hermetic concrete tile production line

Hermetic press: OCEM Type OPA 1440 DS

Year of built 2003 (complete overhaul in 2020 (lower traverse block and pillars with nuts)

High power hydraulics were installed to reduce cycle time to ±10 sec. with 600x600x40.

Main mix doser from Schindler was installed in 2013 for most accurate filling and short cycle time.

The tile extractor was replaced in 2009.

Controls Siemens S7

Including mould equipment 600x600.

Number of steel pallets ±1.100

Maximum product size 600x600x80 mm

Curing capacity 5.500 tiles 600x600 mm

The production line includes everything from the press to the packing line:

• Ocem press OPA 1440 DS with 7 stations and 520 tons of pressing power including pre-pressing station

• Removable face mix disc-doser with crane

• Tile extractor/carrier/turnover from Schauer & Haeberle (vacuum system)

• Automatic transport system for steel pallets into curing chamber

• Overhead crane for stacking layers of 10 steel pallets into the curing chamber

• Climanova curing system with moist control and air circulation

• Heating system for curing chamber

• Vacuum system for picking tiles from the steel pallets onto finishing line

• Pallet cleaning brush

• Calibrator for spacers to make the tiles splinter-free

• Shotblasting unit (built 2015) with dust extraction

• Coatingline with dual spraying system (BM Anlagenbau) and Bürkle roller (3 layers of coating possible)

• Hotmelt device for putting plastic dots on backside of tile to prevent scratching

• Fanuc robot to pack tiles for strapping and placing tiles onto wooden transport pallets

• Automatic strapper

• Automatic palletizer

Still installed. Dismantling and loading not included.

Copyright © 2002-2025 DIT Equip - All rights reserved.