Dosing concrete into the mold

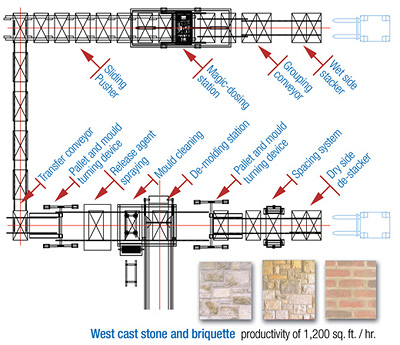

MAGIC-DOSING™ automatic Wet Cast concrete production machine is the most advanced system to fill each incoming mold, even if the concrete requirement of the next mold is different from its predecessor.

No sensors, no chips to recognize the mold, no dosing boxes, just a simple patent pending system to fill each mold accurately for a perfect fill every cycle. In less than 20 seconds, the mold will be filled, vibrated and ready to be handled for curing.

Knowing how important the natural look on a wall is, one will discover how feeding the Magic-Dosing machine with different volume molds will maximize the variety of stone produced.

The benefits of the rapid change of products without having to calibrate dosing boxes of concrete are huge.

|

Handling the pallets and mold

Thanks to the automatic dosing of the mold and to the automatic demolding on the dry side, a variety of optional technologies are now available to handle the pallets. With less than 20 seconds cycle time, the well-known technologies of handling the paving stone are now accessible for wet cast stone.

An elevator on the wet side, a de-elevator on the dry side and finger car obots bringing the pallets to rack curing rooms is a valuable option. Other will prefer to start with a lift truck operation picking up a stack from an utomatic board on board stacker and bringing back the dry product by lift truck to automatically destack and demold.

|